Dalian Production

Accelerating, transforming challenge into success

Location:

109 Dengta Road, Changxiang Island Economic Development District, Dalian, Liaoning, China116433

Newly built, operations formally started in December 2023

Total area of 176m2, that includes 64 buildings

Total Lab Space: 2786m2

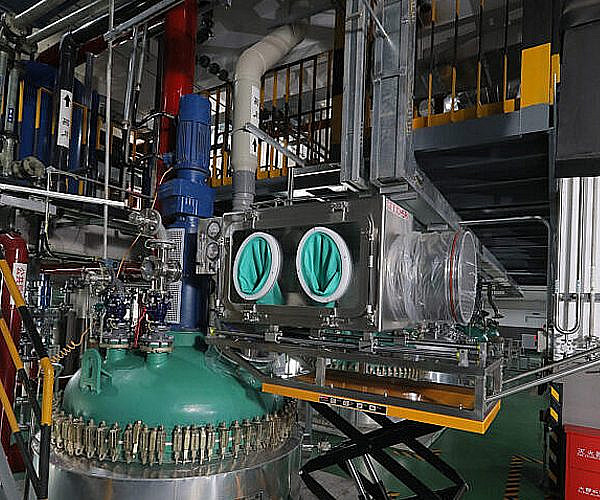

Dedicated GMP production area

11,800m2, twolarge GMP production buildings

- Total of 85 reactors (including 6 hydrogenators, 10MPa max pressure), with a total volume of 125m3

- Production capacity: 100MT annually

- Management system build-up to strictly follow cGMP/FDA/EMA standards

- Successfully obtained China Gov API Drug production permit

Dedicated non-GMP production area:

- 22,800m2, five large production buildings, including:

- 4 intermediates buildings, total 163 reactors with a total volume of 450m3

- 1 hydrogenation building, total 16 hydrogenation reactors: SS, Hastelloy,

pressure up to 8MPa Production capacity: 1000MT annually - Multifunctional workshop: Low temperature(to -80DegC) & Hastelloy reactors

Warehouse facilities: Total storage area of 13,900m2 including:

- 7 class A warehouses, 4 class C warehouses, 1 gas storage warehouse, 1 Haz waste warehouse

- Temperature and humility controlled at ≤ 20oC and 2-8oC.

Waste disposal facilities including

- Wastewater bio-disposal system, with designed 600ton/day capacity

- Waste gas RTO disposal facility

- Waste solid treated by Gov approved Haz waste disposal company

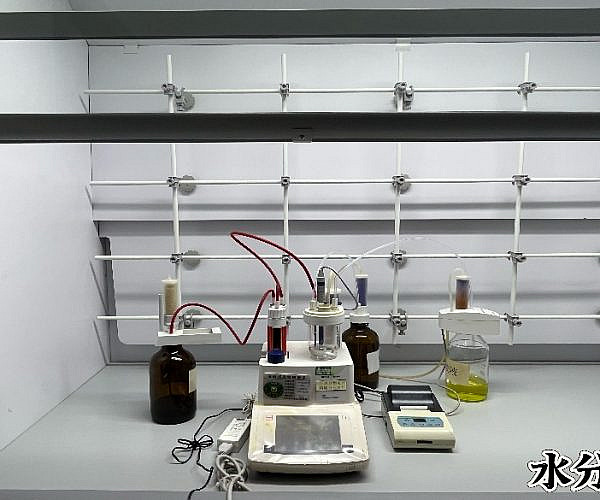

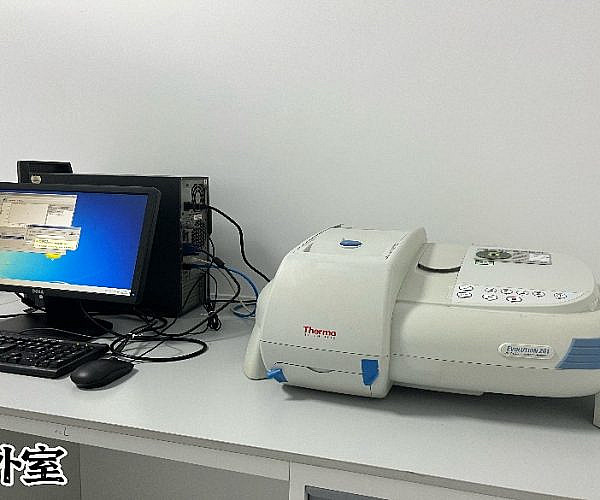

On-site QC facilities including

- 15 HPLCs, Agilent & Waters

- 5 GCs

- GCMS

- IR

- KF, Titration, AA, UV

- Stability chambers

EHS management system

- Strictly following local & international standards. Successful audit (Gov & customer) record

- Process safety evaluation performed for every process step

- DSC, Sedex, RC1 and Hazop analysis

- Production temperature and pressure monitored by DSC. Flow fully automated under digital control

- High standard gas detectors and fire-fighting system installed

- Suitable PPEs defined and well equipped

- Waste-gas treatment and WWTP under control & fully meeting local & international standards

- Training and emergency drills performed on regular basis

Pilot and Commercial Scale Manufacturing

On-site QC Facilities